Research

Approach

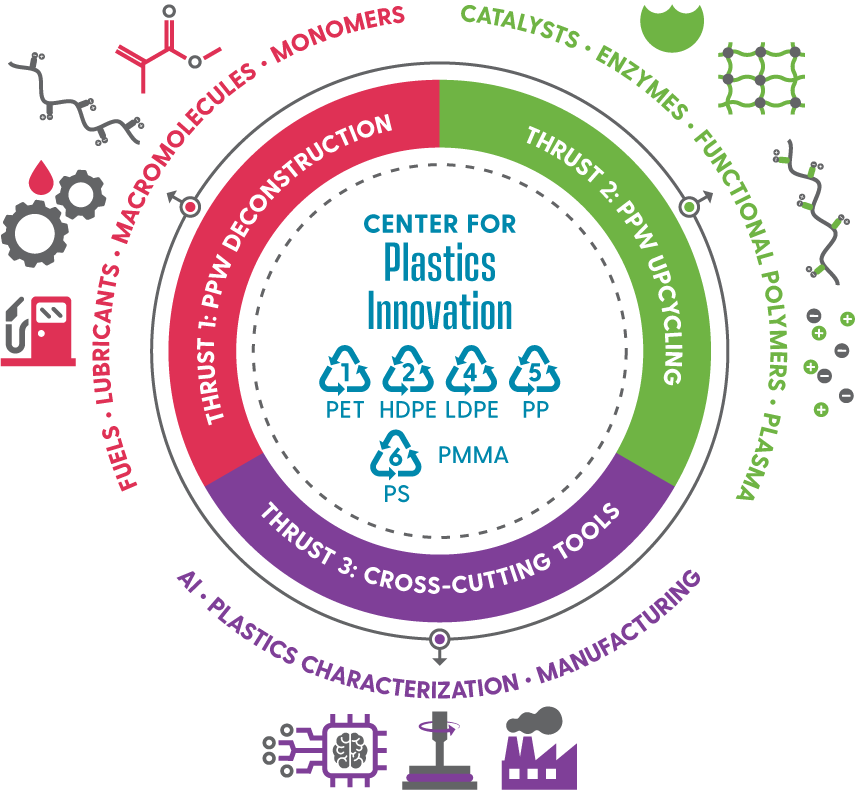

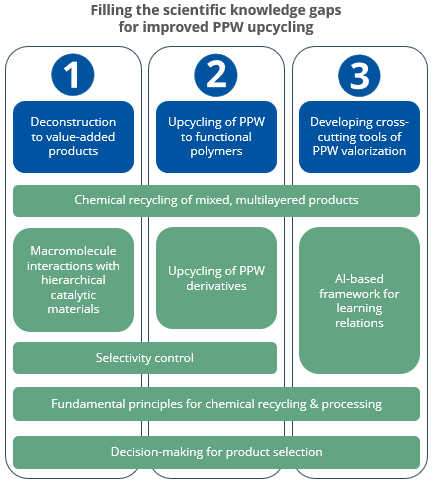

We leverage our expertise in catalysis (synthetic, biological), macromolecular science and engineering, additive manufacturing, data science and artificial intelligence (AI), systems engineering, and computation to address three distinct thrusts:

1) tunable heterogeneous catalysts and microwave (MW) energy for the conversion of PPW into fuels, lubricants, precision macromolecules, and monomers;

(2) functionalization and upcycling using a) plasma-assisted, catalysis and surface treatment, b) photoredox-catalyzed decarboxylation, and c) enzymatic routes to generate high-value monomers and polymers; and,

(3) new cross-cutting tools driven by AI, PPW characterization, macromolecular property prediction through modeling, and additive manufacturing to enable scientific advances.

CPI’s approach overcomes distinct challenges related to PPW upcycling, including PPW diversity and heterogeneity; optimization of macromolecule/catalyst interactions in melt; selectivity control; and development of correlations between plastics manufacturing, chemical recycling, and macromolecular physical properties.

Research Thrusts

Plastics Deconstruction to Value-Added Products

We are advancing the new frontiers of catalysis science to develop higher value polymer products.

Upcycling of PPW to Functional Polymers

Recent plastics recycling has been largely focused on deconstruction to fuels. To diversify the product slate, we are developing transformative approaches to PPW valorization.

Developing Cross-Cutting Tools of PPW Valorization

Cross-cutting tools can enable fundamental studies in the first two thrusts, and drive technological innovation. Using an AI-platform, we integrate physical models, experimental data, and expert knowledge to correlate feedstock composition with catalyst synthesis and characterization, along with depolymerization product composition.