Research Overview

Plastic waste to valuable product

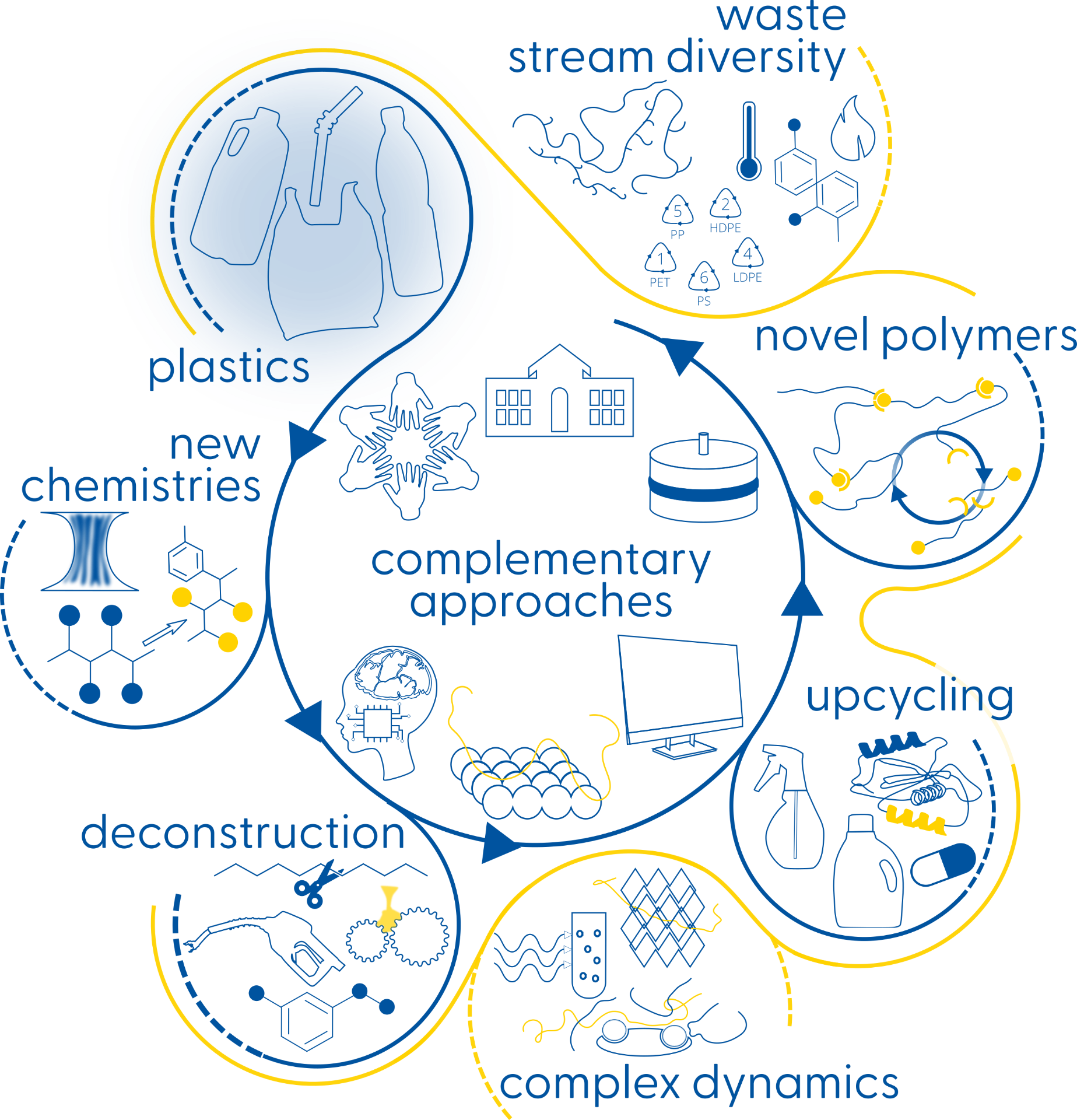

At CPI, we leverage our expertise in catalysis (synthetic, biological), macromolecular science and engineering, additive manufacturing, data science and artificial intelligence (AI), systems engineering, and computation to address complex challenges in plastics sustainability.

Our Approach

Thrust 1

Deconstruction

Tunable heterogeneous catalysts and microwave (MW) energy for the conversion of PPW into fuels, lubricants, precision macromolecules, and monomers.

Thrust 2

Upcycling

Functionalization and upcycling using chemical and biological routes to generate high-value monomers and polymers.

Thrust 3

Cross-Cutting Tools

New cross-cutting tools driven by AI, PPW characterization, macromolecular property prediction through modeling, and additive manufacturing to enable scientific advances.

CPI’s approach overcomes distinct challenges related to PPW upcycling, including PPW diversity and heterogeneity; optimization of macromolecule/catalyst interactions in melt; selectivity control; and development of correlations between plastics manufacturing, chemical recycling, and macromolecular physical properties.

Looking for more details? Browse our research brochures below.

Synergystic Solutions for Complex Problems

Transforming foam with worms

Mealworms possess the microbial power to transform plastics from foam takeout containers and grocery bags into useable precursor chemicals for cosmetics, detergents, and new plastics without intensive chemical processing. By carefully selecting polymer and nutrient sources, highly effective and lower energy processes can be developed.

(*initiated by CPI Seed Initiative) PBS: You Oughta Know. (2022) WHYY

Smarter technology discovery

Computer-aided categorization and interpretation of published scientific literature can help researchers find information faster and can facilitate matching plastics waste streams to innovative technology that can obtain a desired product using minimum energy and cost.

J. App. Cat. B: Envr. (2022) 121873.

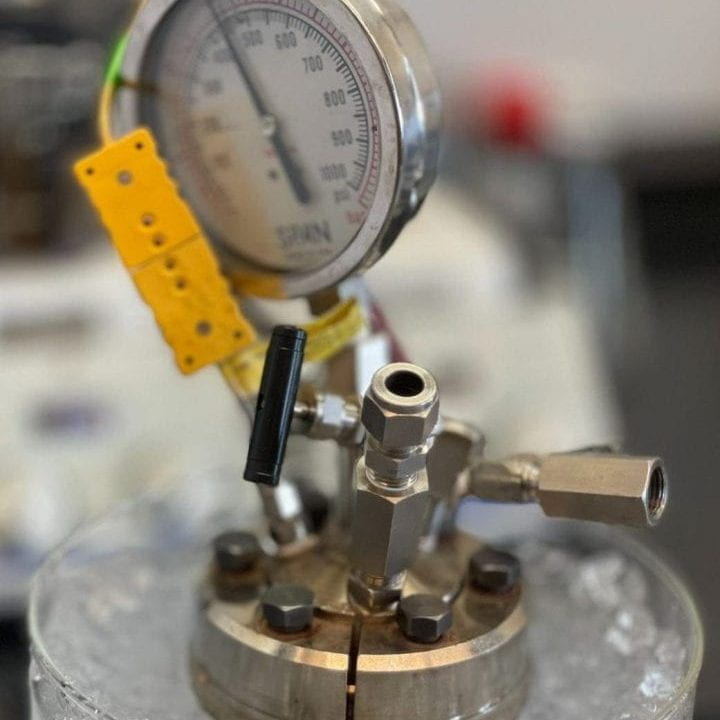

From packaging to lubricants

Using newly developed catalysts, researchers can take common packaging plastics (from detergent bottles or storage containers) and convert them to raw materials for industrial lubricants. Highly specific process design enables targeting of more higher-value products from real waste streams.

J. App. Cat. B: Envr. (2021) 299, 120483.; JACS Au. (2021) 1, 1422.

Old plastics to circular materials

With synergistic process design, researchers can break down traditional household plastics (like plastic bags) and add new chemical functionalities that enable the production of plastics that can be degraded and re-formed on demand, reducing the need for new chemicals for circularity.

J. App. Cat. B: Envr. (2022) 121873.