Research Overview

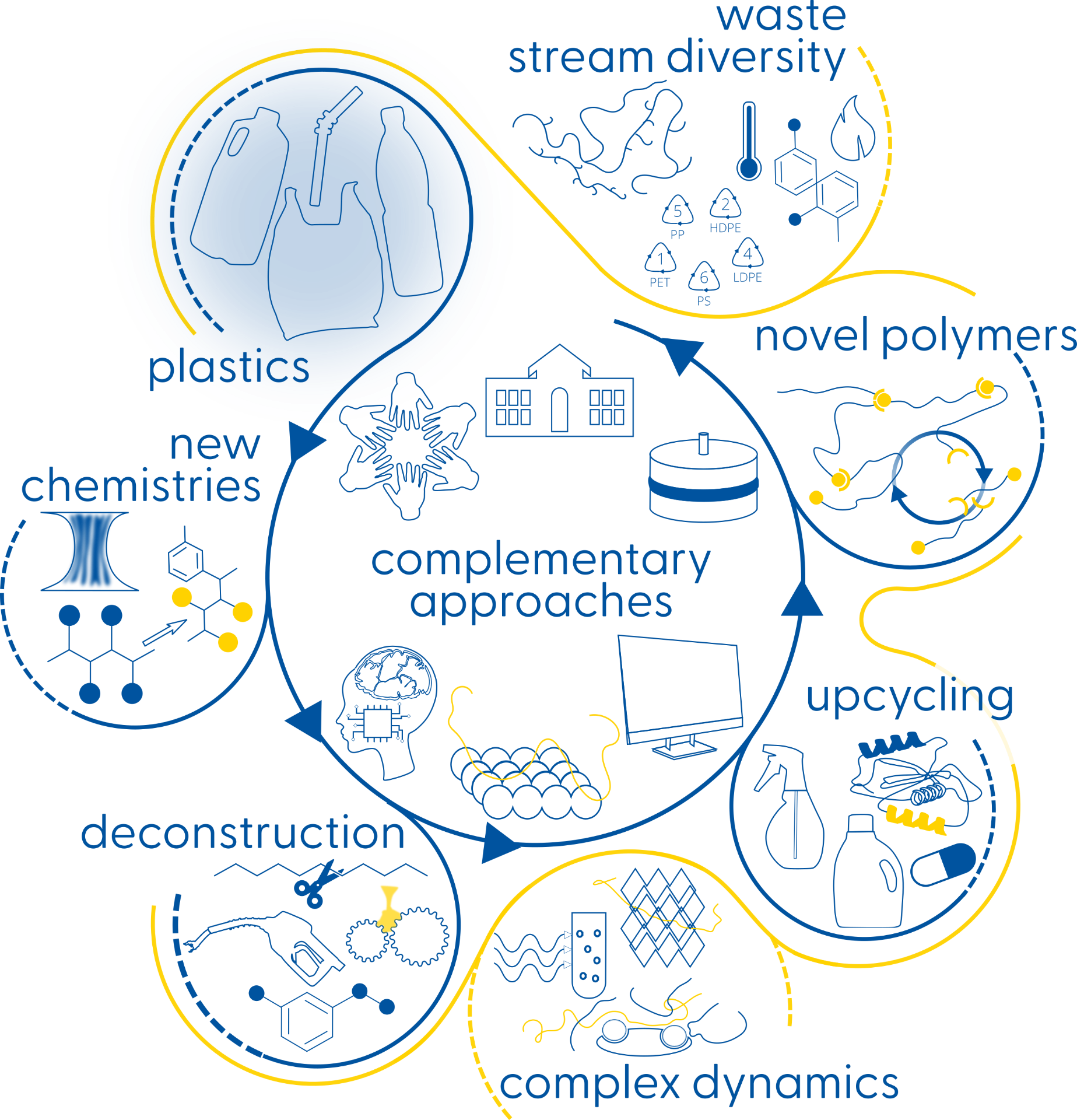

Plastics waste to valuable product

Thrust 1

Non-Polyolefin Waste

Combines experimental deconstruction strategies with computational analysis to enable efficient valorization of vinyl-based and step-growth polymers.

Thrust 2

Complex Waste

Aims to develop catalysts, strategies, and knowledge for handling complex feedstock compositions and common impurities.

Thrust 3

Circular-By-Design

Leverages current plastics waste as building blocks to realize new, reprocessable materials with little cycle-to-cycle property fade and expanded end-of-life optionality.

CPI’s approach utilizes cross-cutting activities across all research thrusts that are organized into four major themes:

Transforming foam with worms

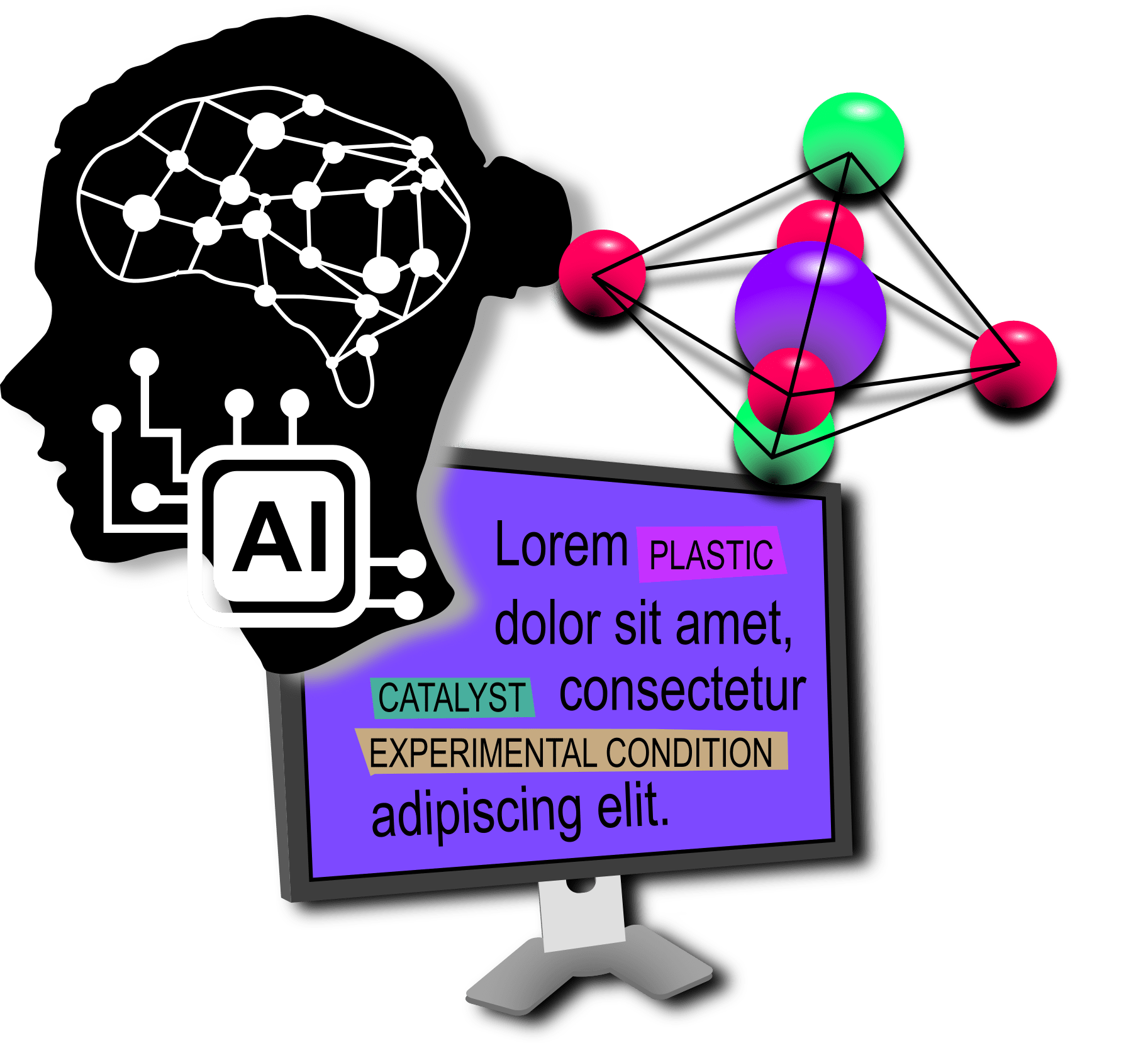

Smarter technology discovery

From packaging to lubricants

Old plastics to circular materials

With synergistic process design, researchers can break down traditional household plastics (like plastic bags) and add new chemical functionalities that enable the production of plastics that can be degraded and re-formed on demand, reducing the need for new chemicals for circularity.

J. App. Cat. B: Envr. (2022) 121873.