Making plastic more recyclable

By Paul Dailing

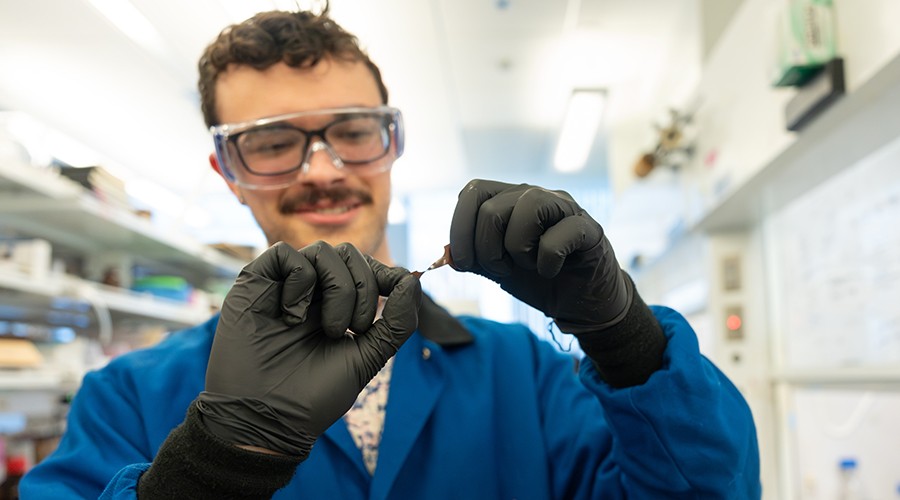

When asked to explain plastics, Pritzker School of Molecular Engineering graduate student Sam Marsden pulled out a paperclip chain and a length of small strings crudely knotted together.

The paperclip chain represented a highly recyclable plastic like the polyethylene terephthalate (PET) found in soda bottles and the fibers in clothes. These can be broken down to the molecular level (the individual paperclips) and rebuilt into like-new materials.

The string represented less-recyclable plastics like the polyethylene of a grocery bag. The initial material can be remade, like chopping up a length of string and tying the pieces back together, but it will never match the original.

“You can try to recycle these types of plastics, but you end up with something that’s just worse quality,” Marsden said.

Finally, Marsden pulled out the end goal of his research in Pritzker Molecular Engineering’s Rowan Group: a series of strings linked by paperclips.

This represents the new form of polymer Marsden is working to create, wherein polyethylene chains can be broken into smaller units with the ends modified to replicate the recyclability of other forms of plastic. It will be a plastic that’s as strong as polyethylene, but as recyclable as PET.

“Sam is taking on one of the most visual and pressing problems of our time,” said PME Prof. Stuart Rowan, Marsden’s principal investigator. “Most plastics were originally designed not to degrade. What happens to the plastic at its end-of-life simply wasn’t a concern when people were designing these polymers over 50 years ago. But polymers and plastics have so many useful properties, that they play a role in almost every part of our daily life, and this has resulted in their production skyrocketing over the years, to a point that their ‘throw away’ disposal is causing issues across the globe.”

Plastics and policy

Plastic is a catchall term for a wide variety of polymers, each with its own traits and flaws. Plastic can be molded, bent, shaped, blown into soft drink bottles, spread into plastic wrap, hardened to protect car passengers or puffed into Styrofoam insulation.

“There’s a reason plastic is everywhere,” Marsden said. “It’s a great material. It has great properties.”

The trouble comes from using these immortal materials for disposable products. The low-density polyethylene of a grocery bag or the polypropylene of a spork are useful for the length of a meal or the drive back from the store, then linger in landfills for centuries.

Historically, for the companies designing and building these packages and products, the recyclability of the material was less of a concern than a polymer’s cost and properties. Polypropylene makes a bad grocery store bag and low-density polyethylene makes a bad spork.

Marsden’s research is currently focused on replacing high-density polyethylene, one of the most produced plastics on the planet. It’s the plastic commonly used in milk jugs. He plans to move on from there to new materials that will replace two other large scale production plastics, low-density polyethylene and polypropylene. But he knows that manufacturers will only switch materials if the price and properties are right.

That’s why Marsden is bolstering his PME education with science policy and international climate policy courses from UChicago’s Harris School of Public Policy. The perfect material in the lab means nothing if it doesn’t go into the market.

“Without any kind of real incentive, a lot of people will use the string rather than trying to get these more sustainable materials,” he said, holding up his example knots.

Reaching out

Marsden can pinpoint the day he realized he wanted to study polymers.

“In my high school chemistry class, a group of graduate students from the University of Massachusetts came by and did a bunch of demos showing off different uses of polymers,” Marsden said. “It just clicked for me then that polymers were something that I was interested in.”

Now Marsden is the one spurring young people’s interest in science, leading demonstrations and talking about his research at South Side middle schools through the PME Science Communications Program.

“During his time at UChicago, Sam has become one of PME’s core outreach leaders,” said Assistant Dean of Education and Outreach Laura Rico-Beck. “He has a keen ability to engage people of all ages and backgrounds without talking down to them or lecturing. It’s such a pleasure to work with him.”

Beyond the fun of talking to young people and the intellectual challenge of finding simple ways to explain complex science – the paperclip example was one he designed for middle schoolers – Marsden sees his outreach efforts as a way of giving back.

“It made a difference for me. I can try to make a difference for some other people too,” Marsden said.